|

|

| Benefits of WaterBoss Nozzles | |

|

|

|

| Low Pressure Series - Variable | |||||

|

WaterBoss 300-1/2-S | ||||

| Low Pressure Series - Variable | |||||

| WaterBoss 300-1/2-L | |||||

WaterBoss Flow Rates for 3/4 inch X 50 foot hose

| WB-300-1/2-L | LOW FLOW TIP | (+) TIP | (++) TIP |

| PSI | GPM | GPM | GPM |

| 50 | 6.5 | 8.5 | 9.5 |

| 100 | 9.25 | 13 | 14 |

| 150 | 11.5 | 15.5 | 17 |

| 200 | 13 | 17 | 19 |

| 250 | 14.5 | 19 | 22 |

| 300 | 15.5 | 21 | 25 |

WaterBoss Flow Rates for 1/2 inch X 50 foot hose

| WB-300-1/2-L | LOW FLOW TIP | (+) TIP | (++) TIP |

| PSI | GPM | GPM | GPM |

| 50 | 6 | 7.5 | 8 |

| 100 | 7 | 10 | 11 |

| 150 | 10 | 12 | 13.5 |

| 200 | 11 | 14 | 15 |

| 250 | 12.5 | 16 | 17 |

| 300 | 14 | 18 | 19 |

| Low Pressure Series - Variable | |||||

| WaterBoss 750-1/2-IL | |||||

WaterBoss Flow Rates for InLine 1/2 inch X 50 foot

| WB-750-1/2-IL InLine | |

| PSI | GPM |

| 100 | 8 |

| 150 | 10 |

| 200 | 11 |

| 250 | 12.5 |

| 300 | 13.5 |

WaterBoss Flow Rates for InLine 3/8 inch X 50 foot

| WB-750-1/2-IL InLine | |

| PSI | GPM |

| 100 | 6 |

| 150 | 7 |

| 200 | 8 |

| 250 | 9 |

| 300 | 9.75 |

| 350 | 11 |

| 400 | 12 |

| 450 | 12.5 |

| 500 | 13 |

| 550 | 13.5 |

| 600 | 14 |

| 650 | 14.5 |

| 700 | 15 |

| 750 | 15.5 |

| Low Pressure Series - Variable | |||||

| WaterBoss 750-1/2-L | |||||

WaterBoss Flow Rates for 1/2 inch X 50 foot hose

| WB-750-1/2-L | ||

| PSI | GPM | |

| 600 | 22 | Difficult to Opperate |

| Low Pressure Series - Variable | |||||

|

WaterBoss 750-1/2-S | ||||

| Low Pressure Series - Variable | |||||

| WaterBoss 750-3/8-L | |||||

WaterBoss Flow Rates for 3/8 inch X 50 foot hose

| WB-750-3/8-L | 750-3/8-LRF Reduced Flow | |

| PSI | GPM | GPM |

| 100 | 5.5 | |

| 150 | 6.5 | |

| 200 | 7.5 | |

| 250 | 8.5 | |

| 300 | 9 | |

| 350 | 10 | 6.75 |

| 400 | 11 | 7 |

| 450 | 12 | 7.5 |

| 500 | 12.5 | 8.5 |

| 550 | 13 | 8.75 |

| 600 | 14 | 9 |

| 650 | 14.5 | 9.25 |

| 700 | 15 | 9.5 |

| 750 | 15.5 | 10 |

| Low Pressure Series - Variable | |||||

| WaterBoss 750-3/8-LRF (Reduced Flow) | |||||

WaterBoss Flow Rates for 3/8 inch X 50 foot hose

| WB-750-3/8-L | 750-3/8-LRF Reduced Flow | |

| PSI | GPM | GPM |

| 100 | 5.5 | |

| 150 | 6.5 | |

| 200 | 7.5 | |

| 250 | 8.5 | |

| 300 | 9 | |

| 350 | 10 | 6.75 |

| 400 | 11 | 7 |

| 450 | 12 | 7.5 |

| 500 | 12.5 | 8.5 |

| 550 | 13 | 8.75 |

| 600 | 14 | 9 |

| 650 | 14.5 | 9.25 |

| 700 | 15 | 9.5 |

| 750 | 15.5 | 10 |

| Low Pressure Series - Variable | |||||

|

WaterBoss 750-3/8-S | ||||

| High Pressure Series* | |||||

| WaterBoss 800-3/8-L | |||||

|

*Utilizes Interchangeable Spray Nozzles and can be used with Spray Wands. |

|||||

| High Pressure Series* | |||||

| WaterBoss 1200-3/8-L | |||||

|

*Utilizes Interchangeable Spray Nozzles and can be used with Spray Wands. |

|||||

|

Superlok i-Fitting are the safest valve and fittings products in the instrumentation and control markets. We are so confident in the Superlok, Zero Leak Technology, that we back all i -Fittings products with a lifetime guarantee against leaks or failures! |

Superlok i-Fitting are the safest valve and fittings products in the instrumentation and control markets. We are so confident in the Superlok Zero Leak Technology, that we back all - fitting products with a lifetime guarantee against leaks or failures

Superlok i-Fitting are the safest valve and fittings products in the instrumentation and control markets. We are so confident in the Superlok Zero Leak Technology, that we back all - fitting products with a lifetime guarantee against leaks or failures

Superlok i-Fitting Tube fittings and valves | JIC Fittings | Ultra-High-Purity Fittings | DIN Fittings | Tubes | Coil | Flexible tube | Manifolds | High Pressure

Superlok i-Fitting - Built in Gap Gauge in Every Fitting Instrumntation Valves, Tube Fittings & Pipe Fittings.

![]()

![]()

![]()

![]()

![]()

![]()

Superlok i - fittings are the safest valve and fittings products in the instrumentation and control markets. We are so confident in the Superlok Zero Leak Technology, that we back all i - fitting products with a lifetime guarantee against leaks or failures.

Superlok i - fittings are the safest valve and fittings products in the instrumentation and control markets. We are so confident in the Superlok Zero Leak Technology, that we back all i - fitting products with a lifetime guarantee against leaks or failures.

Superlok i-Fitting - Built in Gap Gauge in Every Fitting Instrumntation Valves, Tube Fittings & Pipe Fittings. Superlok i-Fitting Tube fittings and valves | JIC Fittings | Ultra-High-Purity Fittings | DIN Fittings | Tubes | Coil | Flexible tube | Manifolds | High Pressure

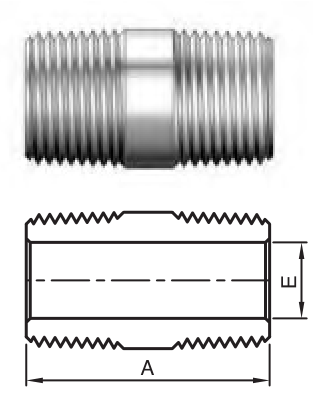

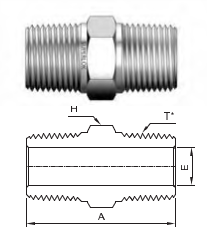

| Male NPT Threads | ||||||

| Male NPT Threads | ||||||

|

NOTE : In case of ISO/BSP(ISO 7/1) tapered pipe thread of T*, The part number should be “NR” instead of “N”

|

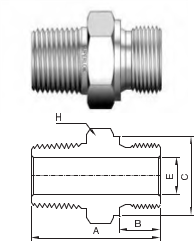

| Male NPT to Male ISO Parallel Pipe Threads | |||||||

|

|

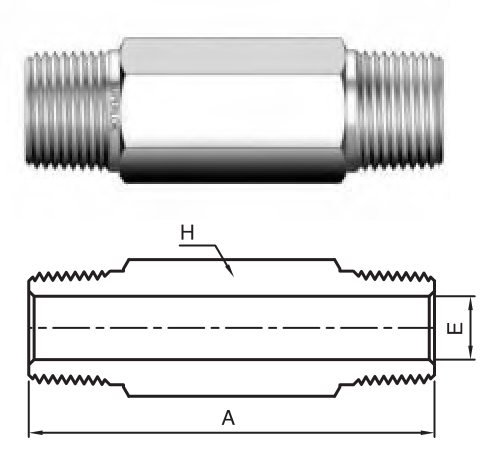

| Male NPT Threads | ||||||

|

NOTE : The length of Nipple “A” is defined by user |

||||||

| Male NPT Threads | ||||||

|

NOTE : The length of Nipple “A” is defined by user

|

| Female to Male NPT Threads | ||||||

|

NOTE : In case of ISO/BSP(ISO 7/1) tapered pipe thread of T* The part number should be “NR” instead of “N”

|

| Female NPT to Male ISO Parallel Pipe Threads | |||||||

|

|

| Female to Male NPT Threads | |||||||

| Female to Male NPT Threads | |||||||

| Female NPT Threads | ||||||

| Female to Male NPT Threads | |||||||

| ISO Parallel Copper Gaskets | ||||||

| Female NPT Threads | ||||||

| Female NPT Threads | ||||||

| SBV120H Series | ||||

|

0.052˝ and 0.406˝ (1.3mm to 10.3mm) |

||||

| SBVI210 Series | ||||

|

5.0mm to 16.0mm |

||||

| SBVFI360 Series | ||||

|

1/16˝ to 3/4˝ and 4mm to 16mm Variety of end connection |

||||

| SBVHI360 Series | ||||

|

10.0mm to 19.0mm |

||||

| SWBI320 Series | ||||

|

-20 to 450°F (-28 to 232°C) with PVDF seat |

||||

| SGBV / SGBV2 Series | ||||

|

0.125” (3.2mm), 0.250” (6.4mm) |

||||

| Integral Bar Stock Bonnet Needle Valve SBNVI Series | ||||

|

0.17˝ and 0.25˝ (4.3mm and 6.4mm) |

||||

| SHCV SERIES | ||||

|

1/3, 1, 5, 10, 25 psig |

||||

| SOCV SERIES | ||||

|

VITON O-ring : -10°F to 375°F (-23°C to 190°C ) |

||||

| SRVL Series | ||||

|

4.8mm |

||||

| SRVH Series | ||||

|

4.8mm |

||||

| SPV130 Series | ||||

|

316 stainless steel |

||||

| STF Series | ||||

|

40°F to 250°F (- 40°C to 121°C) |

||||

| SIF Series | ||||

|

1/8 to 1/2 in. and 3 to 10mm |

||||

Even under extremes of vibration or dynamic loads, the HEICO-LOCK® Wedge Locking System provides maximum reliability.

If the securing system is subject to dynamic stress, movement is only possible between the internal washer surfaces. This results in an increase in the clamping force.

- Certified system for securing bolts, working at low and high preload levels.

- Particularly suitable for dynamic loads – including when using lubricants.

- Can be re-used.

- Very easy to install and remove (wedge lock washers are supplied as a pre-assembled pair).

- Also suitable for high-tensile bolts of 8.8, 10.9 and 12.9 and their respective nuts

- Available in steel or stainless steel with narrow or wide bearing surfaces – other materials are available upon request.

- Available from M3 – M76 and ¼” – 3” - custom sizes upon request.

| M | Steel Item No. | Internal-Ø [mm] | External-Ø [mm] | Box Qty [Pair] |

| 3 | HLS-3 | 3,4 | 7,0 | 200 |

| 3,5 | HLS-3,5 | 3,9 | 7,6 | 200 |

| 4 | HLS-4 | 4,4 | 7,6 | 200 |

| 5 | HLS-5 | 5,4 | 9,0 | 200 |

| 6 | HLS-6 | 6,5 | 10,8 | 200 |

| 8 | HLS-8 | 8,5 | 13,5 | 200 |

| 10 | HLS-10 | 10,7 | 16,6 | 200 |

| 11 | HLS-11 | 11,4 | 18,5 | 200 |

| 12 | HLS-12 | 13,0 | 19,5 | 200 |

| 14 | HLS-14 | 15,2 | 23,0 | 100 |

| 16 | HLS-16 | 17,0 | 25,4 | 100 |

| 18 | HLS-18 | 19,5 | 29,0 | 100 |

| 20 | HLS-20 | 21,4 | 30,7 | 100 |

| 22 | HLS-22 | 23,4 | 34,5 | 100 |

| 24 | HLS-24 | 25,3 | 39,0 | 100 |

| 27 | HLS-27 | 28,4 | 42,0 | 50 |

| 30 | HLS-30 | 31,4 | 47,0 | 50 |

| 33 | HLS-33 | 34,4 | 48,5 | 25 |

| 36 | HLS-36 | 37,4 | 55,0 | 25 |

| 39 | HLS-39 | 40,4 | 58,5 | 25 |

| 42 | HLS-42 | 43,2 | 63,0 | 25 |

| 45 | HLS-45 | 46,2 | 70,0 | 25 |

| 48 | HLS-48 | 49,6 | 75,0 | 25 |

| 52 | HLS-52 | 53,6 | 80,0 | 1 |

| 56 | HLS-56 | 59,1 | 85,0 | 1 |

| 60 | HLS-60 | 63,1 | 90,0 | 1 |

| 64 | HLS-64 | 67,1 | 95,0 | 1 |

| 68 | HLS-68 | 71,1 | 100,0 | 1 |

| 72 | HLS-72 | 75,1 | 105,0 | 1 |

| 76 | HLS-76 | 79,1 | 110,0 | 1 |

| UNC | Steel Item No. | Internal-Ø [mm] | External-Ø [mm] | Box Qty [Pair] |

| 1/4" | HLS-1/4" | 7,2 | 11,5 | 200 |

| 3/8" | HLS-3/8" | 10,3 | 16,6 | 200 |

| 1/2" | HLS-1/2" | 13,5 | 19,5 | 200 |

| 3/4" | HLS-3/4" | 20,0 | 30,7 | 100 |

| 1" | HLS-1" | 27,9 | 39,0 | 100 |

| M | Steel Item No. | Internal-Ø [mm] | External-Ø [mm] | Box Qty [Pair] |

| 3,5 | HLB-3,5 | 3,9 | 9,0 | 200 |

| 4 | HLB-4 | 4,4 | 9,0 | 200 |

| 5 | HLB-5 | 5,4 | 10,8 | 200 |

| 6 | HLB-6 | 6,5 | 13,5 | 200 |

| 8 | HLB-8 | 8,6 | 16,6 | 200 |

| 10 | HLB-10 | 10,7 | 21,0 | 200 |

| 12 | HLB-12 | 13,0 | 25,4 | 100 |

| 14 | HLB-14 | 15,2 | 30,7 | 100 |

| 16 | HLB-16 | 17,0 | 30,7 | 100 |

| 18 | HLB-18 | 19,5 | 34,5 | 100 |

| 20 | HLB-20 | 21,4 | 39,0 | 100 |

| 22 | HLS-22 | 23,4 | 42,0 | 50 |

| 24 | HLB-24 | 25,3 | 48,5 | 50 |

| 27 | HLB-27 | 28,4 | 48,5 | 25 |

| 30 | HLB-30 | 31,4 | 58,4 | 25 |

| 33 | HLB-33 | 34,4 | 58,5 | 25 |

| 36 | HLB-36 | 37,4 | 63,0 | 25 |

| 39 | HLB-39 | 40,4 | 75,5 | 25 |

| UNC | Steel Item No. | Internal-Ø [mm] | External-Ø [mm] | Box Qty [Pair] |

| 1/4" | HLB-1/4" | 7,2 | 13,5 | 200 |

| 3/8" | HLB-3/8" | 10,3 | 21,0 | 200 |

| 1/2" | HLB-1/2" | 13,5 | 25,4/td> | 100 |

| 3/4" | HLB-3/4" | 20,0 | 39,0 | 100 |

| 1" | HLB-1" | 27,9 | 48,5 | 50 |

| M | Steel Item No. | Internal-Ø [mm] | External-Ø [mm] | Box Qty [Pair] |

| 3 | HLS-3S | 3,4 | 7,0 | 200 |

| 3,5 | HLS-3,5S | 3,9 | 7,6 | 200 |

| 4 | HLS-4S | 4,4 | 7,6 | 200 |

| 5 | HLS-5S | 5,4 | 9,0 | 200 |

| 6 | HLS-6S | 6,5 | 10,8 | 200 |

| 8 | HLS-8S | 8,6 | 13,5 | 200 |

| 10 | HLS-10S | 10,7 | 16,6 | 200 |

| 11 | HLS-11S | 11,4 | 18,5 | 200 |

| 12 | HLS-12S | 13,0 | 19,5 | 200 |

| 14 | HLS-14S | 15,2 | 23,0 | 100 |

| 16 | HLS-16S | 17,0 | 25,4 | 100 |

| 18 | HLS-18S | 19,5 | 29,0 | 100 |

| 20 | HLS-20S | 21,4 | 30,7 | 100 |

| 22 | HLS-22S | 23,4 | 34,5 | 100 |

| 24 | HLS-24S | 25,3 | 39,0 | 100 |

| 27 | HLS-27S | 28,4 | 42,0 | 50 |

| 30 | HLS-30S | 31,4 | 47,0 | 50 |

| 33 | HLS-33S | 34,4 | 48,5 | 25 |

| 36 | HLS-36S | 37,4 | 55,0 | 25 |

| 39 | HLS-39S | 40,4 | 58,5 | 25 |

| 42 | HLS-42S | 43,2 | 63,0 | 25 |

| 45 | HLS-45S | 46,2 | 70,0 | 25 |

| 48 | HLS-48S | 49,6 | 75,0 | 25 |

| 52 | HLS-52S | 53,6 | 80,0 | 1 |

| 56 | HLS-56S | 59,1 | 85,0 | 1 |

| 60 | HLS-60S | 63,1 | 90,0 | 1 |

| 64 | HLS-64S | 67,1 | 95,0 | 1 |

| 68 | HLS-68S | 71,1 | 100,0 | 1 |

| 72 | HLS-72S | 75,1 | 105,0 | 1 |

| 76 | HLS-76S | 79,1 | 110,0 | 1 |

| UNC | Steel Item No. | Internal-Ø [mm] | External-Ø [mm] | Box Qty [Pair] |

| 1/4" | HLS-1/4"S | 7,2 | 11,5 | 200 |

| 3/8" | HLS-3/8"S | 10,3 | 16,6 | 200 |

| 1/2" | HLS-1/2"S | 13,5 | 19,5 | 200 |

| 3/4" | HLS-3/4"S | 20,0 | 30,7 | 100 |

| 1" | HLS-1"S | 27,9 | 39,0 | 100 |

| M | Steel Item No. | Internal-Ø [mm] | External-Ø [mm] | Box Qty [Pair] |

| 3,5 | HLB-3,5S | 3,9 | 9,0 | 200 |

| 4 | HLB-4S | 4,4 | 9,0 | 200 |

| 5 | HLB-5S | 5,4 | 10,8 | 200 |

| 6 | HLB-6S | 6,5 | 13,5 | 200 |

| 8 | HLB-8S | 8,6 | 16,6 | 200 |

| 10 | HLB-10S | 10,7 | 21,0 | 200 |

| 12 | HLB-12S | 13,0 | 25,4 | 100 |

| 14 | HLB-14S | 15,2 | 30,7 | 100 |

| 16 | HLB-16S | 17,0 | 30,7 | 100 |

| 18 | HLB-18S | 19,5 | 34,5 | 100 |

| 20 | HLB-20S | 21,4 | 39,0 | 100 |

| 22 | HLB-22S | 23,4 | 42,0 | 50 |

| 24 | HLB-24S | 25,3 | 48,5 | 50 |

| 27 | HLB-27S | 28,4 | 48,5 | 25 |

| 30 | HLB-30S | 31,4 | 58,4 | 25 |

| 33 | HLB-33S | 34,4 | 58,5 | 25 |

| 36 | HLB-36S | 37,4 | 63,0 | 25 |

| 39 | HLB-39S | 40,4 | 75,5 | 25 |

| UNC | Steel Item No. | Internal-Ø [mm] | External-Ø [mm] | Box Qty [Pair] |

| 1/4" | HLB-1/4"S | 7,2 | 13,5 | 200 |

| 3/8" | HLB-3/8"S | 10,3 | 21,0 | 200 |

| 1/2" | HLB-1/2"S | 13,5 | 25,4/td> | 100 |

| 3/4" | HLB-3/4"S | 20,0 | 39,0 | 100 |

| 1" | HLB-1"S | 27,9 | 48,5 | 50 |

| M | Steel Item No. | Internal-Ø [mm] | External-Ø [mm] | Box Qty [Pair] |

| 3 | HLS-3SMO254 | 3,4 | 7,0 | 200 |

| 3,5 | HLS-3,5SMO254 | 3,9 | 7,6 | 200 |

| 4 | HLS-4SMO254 | 4,4 | 7,6 | 200 |

| 5 | HLS-5SMO254 | 5,4 | 9,0 | 200 |

| 6 | HLS-6SMO254 | 6,5 | 10,8 | 200 |

| 8 | HLS-8SMO254 | 8,6 | 13,5 | 200 |

| 10 | HLS-10SMO254 | 10,7 | 16,6 | 200 |

| 11 | HLS-11SMO254 | 11,4 | 18,5 | 200 |

| 12 | HLS-12SMO254 | 13,0 | 19,5 | 200 |

| 14 | HLS-14SMO254 | 15,2 | 23,0 | 100 |

| 16 | HLS-16SMO254 | 17,0 | 25,4 | 100 |

| 18 | HLS-18SMO254 | 19,5 | 29,0 | 100 |

| 20 | HLS-20SMO254 | 21,4 | 30,7 | 100 |

| 22 | HLS-22SMO254 | 23,4 | 34,5 | 100 |

| 24 | HLS-24SMO254 | 25,3 | 39,0 | 100 |

| 27 | HLS-27SMO254 | 28,4 | 42,0 | 50 |

| 30 | HLS-30SMO254 | 31,4 | 47,0 | 50 |

| 33 | HLS-33SMO254 | 34,4 | 48,5 | 25 |

| 36 | HLS-36SMO254 | 37,4 | 55,0 | 25 |

| UNC | Steel Item No. | Internal-Ø [mm] | External-Ø [mm] | Box Qty [Pair] |

| 1/4" | HLS-1/4"SMO254 | 7,2 | 11,5 | 200 |

| 3/8" | HLS-3/8"SMO254 | 10,3 | 16,6 | 200 |

| 1/2" | HLS-1/2"SMO254 | 13,5 | 19,5 | 200 |

| 3/4" | HLS-3/4"SMO254 | 20,0 | 30,7 | 100 |

| 1" | HLS-1"SMO254 | 27,9 | 39,0 | 100 |

| M | Steel Item No. | Internal-Ø [mm] | External-Ø [mm] | Box Qty [Pair] |

| 3,5 | HLB-3,5SMO254 | 3,9 | 9,0 | 200 |

| 4 | HLB-4SMO254 | 4,4 | 9,0 | 200 |

| 5 | HLB-5SMO254 | 5,4 | 10,8 | 200 |

| 6 | HLB-6SMO254 | 6,5 | 13,5 | 200 |

| 8 | HLB-8SMO254 | 8,6 | 16,6 | 200 |

| 10 | HLB-10SMO254 | 10,7 | 21,0 | 200 |

| 12 | HLB-12SMO254 | 13,0 | 25,4 | 100 |

| 14 | HLB-14SMO254 | 15,2 | 30,7 | 100 |

| 16 | HLB-16SMO254 | 17,0 | 30,7 | 100 |

| 18 | HLB-18SMO254 | 19,5 | 34,5 | 100 |

| 20 | HLB-20SMO254 | 21,4 | 39,0 | 100 |

| 22 | HLB-22SMO254 | 23,4 | 42,0 | 50 |

| 24 | HLB-24SMO254 | 25,3 | 48,5 | 50 |

| 27 | HLB-27SMO254 | 28,4 | 48,5 | 25 |

| 30 | HLB-30SMO254 | 31,4 | 58,4 | 25 |

| 33 | HLB-33SMO254 | 34,4 | 58,5 | 25 |

| 36 | HLB-36SMO254 | 37,4 | 63,0 | 25 |

| 39 | HLB-39SMO254 | 40,4 | 75,5 | 25 |

| UNC | Steel Item No. | Internal-Ø [mm] | External-Ø [mm] | Box Qty [Pair] |

| 1/4" | HLB-1/4"SMO254 | 7,2 | 13,5 | 200 |

| 3/8" | HLB-3/8"SMO254 | 10,3 | 21,0 | 200 |

| 1/2" | HLB-1/2"SMO254 | 13,5 | 25,4/td> | 100 |

| 3/4" | HLB-3/4"SMO254 | 20,0 | 39,0 | 100 |

| 1" | HLB-1"SMO254 | 27,9 | 48,5 | 50 |

| M | Steel Item No. | Internal-Ø [mm] | External-Ø [mm] | Box Qty [Pair] |

| 3 | HLS-3ALL718 | 3,4 | 7,0 | 200 |

| 3,5 | HLS-3,5ALL718 | 3,9 | 7,6 | 200 |

| 4 | HLS-4ALL718 | 4,4 | 7,6 | 200 |

| 5 | HLS-5ALL718 | 5,4 | 9,0 | 200 |

| 6 | HLS-6ALL718 | 6,5 | 10,8 | 200 |

| 8 | HLS-8ALL718 | 8,5 | 13,5 | 200 |

| 10 | HLS-10ALL718 | 10,7 | 16,6 | 200 |

| 11 | HLS-11ALL718 | 11,4 | 18,5 | 200 |

| 12 | HLS-12ALL718 | 13,0 | 19,5 | 200 |

| 14 | HLS-14ALL718 | 15,2 | 23,0 | 100 |

| 16 | HLS-16ALL718 | 17,0 | 25,4 | 100 |

| 18 | HLS-18ALL718 | 19,5 | 29,0 | 100 |

| 20 | HLS-20ALL718 | 21,4 | 30,7 | 100 |

| 22 | HLS-22ALL718 | 23,4 | 34,5 | 100 |

| 24 | HLS-24ALL718 | 25,3 | 39,0 | 100 |

| M | Steel Item No. | Internal-Ø [mm] | External-Ø [mm] | Box Qty [Pair] |

| 3,5 | HLB-3,5ALL718 | 3,9 | 9,0 | 200 |

| 4 | HLB-4ALL718 | 4,4 | 9,0 | 200 |

| 5 | HLB-5ALL718 | 5,4 | 10,8 | 200 |

| 6 | HLB-6ALL718 | 6,5 | 13,5 | 200 |

| 8 | HLB-8ALL718 | 8,6 | 16,6 | 200 |

| 10 | HLB-10ALL718 | 10,7 | 21,0 | 200 |

| 12 | HLB-12ALL718 | 13,0 | 25,4 | 100 |

| 14 | HLB-14ALL718 | 15,2 | 30,7 | 100 |

| 16 | HLB-16ALL718 | 17,0 | 30,7 | 100 |

| 18 | HLB-18ALL718 | 19,5 | 34,5 | 100 |

| 20 | HLB-20ALL718 | 21,4 | 39,0 | 100 |

| 22 | HLS-22ALL718 | 23,4 | 42,0 | 50 |

| 24 | HLB-24ALL718 | 25,3 | 48,5 | 50 |

HEICO-LOCK® Ring Lock Washers provide high-quality, user-friendly bolt securing for the most demanding of applications and are ideal for repeated use.

DESIGN OF THE RING LOCKING SYSTEM

HEICO-LOCK® Ring Lock Washers are supplied pre-assembled. The ring locking system consists of a polyamide ring (PA) and the already familiar HEICO-LOCK® Wedge Lock Washers.

- Very easy to install and remove (ring locking system is supplied pre-assembled)

- Whereas the HEICO-LOCK® Wedge Lock Washers secure the bolted connections reliably,

the ring holds the two individual washers together in the correct position permanently - Particularly suitable for dynamic loads – including when lubricants are used

- Also suitable for use with high-tensile bolts of 8.8, 10.9 and 12.9 and their respective nuts

- Available from M4 – M24 - custom sizes upon request

| M | UNC | Steel Item No. | Stainless Steel Item No. | Internal-Ø [mm] | External-Ø [mm] | Box Qty [Pair] |

| M4 | #8 | HLRB-4 | HLRB-4S | 4,4 | 9,0 | 200 |

| M5 | #10 | HLRS-5 | HLRS-5S | 5,4 | 9,0 | 200 |

| M5 | #10 | HLRS-5 | HLRS-5S | 5,4 | 10,8 | 200 |

| M6 | - | HLRS-6 | HLRS-6S | 6,5 | 10,8 | 200 |

| M6 | - | HLRS-6 | HLRS-6S | 6,5 | 13,5 | 200 |

| - | 1/4“ | HLRB-1/4“ | HLRB-1/4“S | 7,2 | 13,5 | 200 |

| M8 | 5/16“ | HLRS-8 | HLRS-8S | 8,6 | 13,5 | 200 |

| M8 | 5/16“ | HLRS-8 | HLRS-8S | 8,6 | 16,6 | 200 |

| M10 | - | HLRS-10 | HLRS-10S | 10,7 | 16,6 | 200 |

| M10 | - | HLRS-10 | HLRS-10S | 10,7 | 19,5 | 200 |

| M12 | - | HLRS-12 | HLRS-12S | 13,0 | 19,5 | 200 |

| M12 | - | HLRS-12 | HLRS-12S | 13,0 | 25,4 | 100 |

| - | 1/2“ | HLRS-1/2“ | HLRS-1/2“S | 13,5 | 19,5 | 200 |

| M14 | 9/16“ | HLRS-14 | HLRS-14S | 15,2 | 30,7 | 100 |

| M16 | 5/8“ | HLRS-16 | HLRS-16S | 17,0 | 25,4 | 100 |

| M16 | 5/8“ | HLRS-16 | HLRS-16S | 17,0 | 30,7 | 100 |

| - | 3/4“ | HLRS-3/4“ | HLRS-3/4“S | 20,0 | 30,7 | 100 |

| - | 3/4“ | HLRS-3/4“ | HLRS-3/4“S | 20,0 | 39,0 | 100 |

| M20 | - | HLRS-20 | HLRS-20S | 21,4 | 30,7 | 100 |

| M20 | - | HLRS-20 | HLRS-20S | 21,4 | 39,0 | 100 |

| - | 1“ | HLRS-1“ | HLRS-1“S | 27,9 | 39,0 | 100 |

The HEICO-LOCK® Wedge Lock Nut is a re-usable one piece design that delivers high quality, user friendly bolt security without the need for seperate fasteners.

- The one piece design eliminates the risk of misuse

- Minimized risk of operating and production breakdowns caused by faulty bolted connections

- Easy handling especially in hard to reach locations

- Fixed permanently in the correct position

- Reduction of assembly time and effort

- Reduced complexity of the component due to less individual parts

- Easy, safe and fast installation even for non-specialist users

- Can be re-used

- Available from M6 – M27 in strength class 10

- Also available with fine thread: M20x1.5 and M22x1.5

| M | Steel Item No. | External-Ø [mm] | Box Qty [Pair] |

| M6 | HLM-6 | 14,2 | 100 |

| M8 | HLM-8 | 17,9 | 100 |

| M10 | HLM-10 | 21,8 | 50 |

| M12 | HLM-12 | 26,0 | 50 |

| M14 | HLM-14 | 29,9 | 30 |

| M16 | HLM-16 | 34,5 | 25 |

| M18 | HLM-18 | 38,0 | 20 |

| M20 | HLM-20 | 42,8 | 10 |

| M22 | HLM-22 | 46,0 | 10 |

| M24 | HLM-24 | 51,0 | 5 |

| M27 | HLM-27 | 56,0 | 5 |

| Fine Thread | Steel Item No. | External-Ø [mm] | Box Qty [Pair] |

| M20 x 1.5 | HLM-20x1.5 | 42,8 | 1/10 |

| M22 x 1.5 | HLM-22x1.5 | 46,0 | 1/10 |

The HEICO-LOCK® Wheel Nut is the reliable solution for the problem of self-loosening of wheel nuts on both roads and rough terrain.

Design of the Wheel Nut

The HEICO-LOCK® Wheel Nut is supplied pre-assembled. The nut and the HEICO-LOCK® Wedge Lock Washers are combined in a captive and rotary way, ensuring the HEICO-LOCK® Wedge Lock Washers and the nut are fixed permanently in the correct position with the wedge lock washers securing your bolted joint using the proven HEICO-LOCK® principle without loss of quality or function.

- Significantly reduced risk of accidents caused by loosening of wheel nuts.

- Easy handling due to pre-assembled combination.

- Minimized risk of operating and production breakdowns caused by faulty bolted connections.

- Reduction of assembly time and effort.

- Easy, safe and fast installation even for non-specialist users.

- Reusable up to multiple times.

- Suitable for all common steel disc wheels.

- Available in M20x1.5, M22x1.5 and 7/8“-11 BSF; other sizes upon request.

| Fine Thread | Steel Item No. | External-Ø [mm] | Box Qty [Piece] |

| M20 x 1.5 | HLM-20x1.5 | 42,8 | 1/10 |

| M22 x 1.5 | HLM-22x1.5 | 46,0 | 1/10 |

The HEICO-LOCK® HLK-Washers offer high quality anti-vibration security for HV sets according to DIN EN 14399-4 and DIN EN 14399-8.

- Designed to secure HV sets according to DIN EN 14399-4 and DIN EN 14399-8.

- Replacing washers according to DIN EN 14399-6.

- Can be used for bolted connections of cat. A to E according to DIN EN 1993-1-8, a. o. suitable for slip-resistant connections.

- Certified construction product (certificate of conformity).

- Approved for use by General Building Supervisory Authority (DIBt) Approval No Z-14.4-702.

- Approved for railway-specific applications (EBA approval).

- Very easy to install and remove (HLK-washers are supplied as a pre-assembled pair).

- The double chamfer also ensures that the HEICO-LOCK® HLK-Washers cannot be applied incorrectly, so avoiding operator error.

- High corrosion resistance provided by use of a zinc-flake coating.

- Available for HV sets from M12 up to M36.

| M | Steel Item No. | Internal-Ø [mm] | External-Ø [mm] | Box Qty [Pair] |

| M12 | HLK-12 | 13,0 | 24,0 | 200 |

| M16 | HLK-16 | 17,0 | 30,0 | 100 |

| M20 | HLK-20 | 21,0 | 37,0 | 100 |

| M22 | HLK-22 | 23,0 | 39,0 | 50 |

| M24 | HLK-24 | 25,0 | 44,0 | 50 |

| M27 | HLK-27 | 28,0 | 50,0 | 25 |

| M30 | HLK-30 | 31,0 | 56,0 | 25 |

| M36 | HLK-36 | 37,0 | 66,0 | 25 |

| M | Steel Item No. | Reduced standard preload force Fp,C,HLK [kN] | Modified torque method Tightening torque MA, HLK [Nm] | Modified combined method Preliminary tightening torque 1) MA, MKV, HLK [Nm] |

| M12 | HLK-12 | 45 | 150 | 100 |

| M16 | HLK-16 | 80 | 330 | 210 |

| M20 | HLK-20 | 120 | 560 | 365 |

| M22 | HLK-22 | 145 | 730 | 475 |

| M24 | HLK-24 | 165 | 880 | 575 |

| M27 | HLK-27 | 200 | 1160 | 755 |

| M30 | HLK-30 | 252 | 1580 | 1030 |

| M36 | HLK-36 | 367 | 2530 | 1650 |

The efficient combined securing system for highly loaded bolted connections

HEICO-LOCK® Combi-Washers enable quick and easy assembly, especially in difficult installation situations. Combine the simple to use HEICO-LOCK® Combi-Washers with all commercially available bolts provided by your suppliers, quickly and easily.

- Easy mounting and permanent connection thanks to the inset tabs.

- Can be combined with all commercially available bolts.

- Also available in small purchase quantities.

- Flexible use for various different types of bolts.

- Permanent securing and correct positioning of HEICO-LOCK® Wedge Lock Washers.

- Can be re-used several times.

- Cost savings through increased productivity.

- Available in steel or stainless steel with narrower and wider contact areas.

- Available from M8 to M16.

- Can be supplied completely pre-assembled on request.

| M | Steel Item No. | Stainless Steel Item No. | External-Ø [mm] | Box Qty [Pair] |

| 8 | HKS-8 | HKS-8S | 14,0 | 200 |

| 8 | HKS-8 | HKS-8S | 16,6 | 200 |

| 10 | HKS-10 | HKS-10S | 16,9 | 200 |

| 10 | HKS-10 | HKS-10S | 21,0 | 200 |

| 12 | HKS-12 | HKS-12S | 19,5 | 200 |

| 12 | HKS-12 | HKS-12S | 25,4 | 100 |

| 16 | HKS-16 | HKS-16S | 25,4 | 100 |

| 16 | HKS-16 | HKS-16S | 30,7 | 100 |

For a secure joint with a HEICO-TEC® Tension Nut, no electric, hydraulic, or pneumatic tools are needed. All you need is a torque wrench.

TENSION NUTS ACCORDING TO ISO 898-2

HEICO-TEC® Tension Nuts in strength class 8 and 10 meet all the requirements of ISO 898-2 which enables you to easily replace any hex nut from the same strength class while also offering all the advantages of a hand-tightened nut.

Our standard program of HEICO-TEC® Tension Nuts offers you the following advantages:

Fast delivery: On stock and therefore directly available

Compatible with DIN EN ISO 898-2: Direct replacement of hex nuts from the same strength class possible

Extended service through consultation as well as installation aids for technical documentation (e.g. assembly template)

In addition to the HEICO-TEC® standard range, we manufacture special tension nuts according to customer specifications. We can tailor HEICO-TEC® Tension Nuts suitable to your specific application. Other strength classes, sizes or thread pitches are also possible as are tension nuts made from special materials or with special coatings.

ADVANTAGES:

- Product is optimally matched to your application

- High, technical production know-how

- Contact on site

- Project supervision by trained personnel

HEICO-TEC® Reaction Nuts are the ideal complement to the HEICO-TEC® Tension Nut for use with through-bolted connections.

If you already enjoy the advantages of HEICO-TEC® Tension Nuts for active pre-tensioning, you need an equivalent reactive nut on the opposite end. Due to their special shape, HEICO-TEC® Reaction Nuts can flex elastically. And the more elastic a bolted joint is, the more durable and secure it is against untightening and loosening.

ADVANTAGES OF THE HEICO-TEC® REACTION NUT:

- Even load distribution through concave contact surface

- Preload losses are effectively reduced

- No additional space is required, tension nuts and reaction nuts have the same dimensions

COMPATIBLE WITH ISO 898-2

HEICO-TEC® Reaction Nuts meet all requirements of ISO 898-2. They therefore have the same strength as conventional hex nuts and can replace them 1:1. However, they must not be used for active pre-tensioning, rather only on the opposite reactive end.

Due to its unique design, the HEICO-TEC® Tension Nut can be tightened and untightened by hand, making installation easy, reliable and safe.

For use in serial production, HEICO have developed the HEICO-TEC® Multi-Tool. This tool allows the simultaneous tightening of all the pressure bolts, simply by the press of a button, without any additional force being required by the installation personnel.

ADVANTAGES OF THE HEICO-TEC® MULTI-TOOL:

- Simultaneous tightening of all the pressure bolts without any additional force being required

- Multi-Tool is easily mounted using spring-loaded sockets

- Existing hydraulic units can be used without any problem

- For optimized serial applications

DESIGN AND FUNCTION

The HEICO-TEC® Multi-Tool is equipped with spindles for each pressure bolt which are driven hydraulically. This ensures that each pressure bolt is tightened with the exact same torque. With the HEICO-TEC® Multi-Tool subsequent manual checking with a torque wrench, as is common with other tools, is no longer required, saving precious time.

The HEICO-TEC® Multi-Tool is easily mounted using spring-loaded sockets. During further alignment of the tool the sockets snap in place automatically.

The HEICO-TEC® Multi-Tool is driven by a hydraulic unit incorporating a pump, controls and an oil container. You can either use your existing hydraulic unit or purchase one from HEICO, if preferred.

The torque can be selected by adjusting the hydraulic pressure on a pressure valve. A helpful conversion table is provided along with any HEICO-TEC® Multi-Tool supplied.

HEICO offers protection caps for all standard series HEICO-TEC® Tension Nuts.

The HEICO-TEC® Protection Caps, made of durable elastomer, protect the entire tension nut from external, aggressive influences during operation. In combination with coated HEICO-TEC® Tension Nuts, they are particularly suitable for use in highly corrosive environments, e.g. offshore.

The HEICO-TEC® Protection Caps are greased before assembly and then easily fit onto the tension nuts.

ADVANTAGES OF THE HEICO-TEC® PROTECTION CAPS:

- Water-repellent and additionally protects HEICO-TEC® Tension Nuts from corrosion

- Protects against severe damage

- Available to fit all products of the HEICO-TEC® Tension Nut standard series

Incorrect assembly and disassembly can damage pressure bolts, pressure pins or the load bearing washer of the HEICO-TEC® Tension Nut. During maintenance these parts could even be lost entirely. For such scenarios HEICO offer assembly or replacement kits.

These kits are available for standard series HEICO-TEC® Tension Nuts of strength classes 8 and 10, including the respective number of pressure bolts and pins as well as the hardened washer.

Replacement pressure bolts, pressure pins and washers are supplied as a complete kit only, not separately.

Assembly is fast and simple with HEICO-TEC® Tension Nuts. In addition to assembly instructions, an assembly template is also available for the standard product range.

The template helps installers tighten the pressure bolts correctly. The template is attached to the tension nut. The pressure bolts are tightened in sequence, according to a colour system: For example, first the orange-coloured then the blue and finally the white. This cycle is repeated until the torque wrench indicates the required tightening torque is achieved.

For easy documentation, the required tightening torque can be noted on the template. This template can be archived with the date as proof the procedure was carried out correctly.

To protect highly stressed parts of the HEICO-TEC® Tension Nut and to maintain constant friction values, HEICO recommends the use of the HEICO-TEC® Assembly Paste as a protective, release and lubricating agent.

The HEICO-TEC® Assembly Paste contains optimally matched solids and selected additives and offers long-lasting protection against corrosion, seizing and abrasion.

The HEICO-TEC® HDS (Heavy-Duty Sockets) impact sockets are the ideal supplement for the professional assembly of HEICO-TEC® Tension Nuts.

HEICO-TEC® HDS impact sockets are particularly designed for heavy-duty applications and, in contrast to conventional sockets, providing a higher load capacity and a long wear resistance. HEICO also offers a long version in addition to the standard impact sockets. This makes it possible to reach complex applications without any problems (e.g. with heavily protruding bolts).

| Face Protection | Eye Protection | Head Protection | Hearing Protection | Respirators | Welding Helmets |

|

|||||

| FleetKleen - Bio Cleaner & Degreaser |

|

FleetKleen utilizes bioremedial technology to literally “eat” grease, oil, and hydrocarbons off any hard surface. This process uses naturally occurring, harmless micro-organisms with specially formulated bio-surfactants to degrade these hydrocarbons. Fueling Stations, Oil Storage, Concrete Walls & Walkways, Manufacturing Floors, Hydraulic Line Breaks and more. |

|

General House-Keeping Vehicle Parking Area Pumping Stations Concrete Walls Brick & Gravel Areas Vehicle Maintenance Areas |

|

FleetKleen is a new concept in the cleaning and degreasing of concrete floors, metal grating, cement and most solid surfaces. FleetKleen utilizes Bio-Remedial technology to literally "EAT" grease, oil and hydrocarbons off any hard surface. This process uses naturally occurring, harmless micro-organisms with specially formulated bio-surfactants to degrade these hydrocarbons. FleetKleen contains NO SOLVENTS and is NON-FLAMABLE. It is NON-TOXIC, NON-HAZARDOUS, NON-CORROSIVE, and NON-CAUSTIC. When FleetKleen is used in a routine maintenance program, it will effectively help to maintain a clean and safe environment while effectively and economically eliminating hazardous hydrocarbon pollution in the work place. |

| FleetKleen Bio Cleaner & Degreaser comes in | |||

|

55 Gallon Drums |

|||

| Satisfied users include | ||

|

US Air Force US Navy British Airways |

||

| SpillAway+ Hydrocarbon Absorbent |

|

It is a multi-use absorbent with bioremedial microbes for hydrocarbon spills. Spillaway+ absorbs and degrades oil, fuel and petroleum hydrocarbons into harmless, environmentally safe by-products. |

|

Hydraulic Line Breaks Tool Shops Chemical Storage Area Maintenance Areas Pumping Stations Vehicle Maintenance Areas |

|

SpillAway+ introduces a new era in the absorption and disposal of hydrocarbon contaminants in the work place. It is an active mixture of hydrocarbon-oxidizing, naturally occurring, single-celled micro-organisms with a highly efficient pharmaceutical grade absorbency. Ideal solution to absorb oil, diesel fuel, gasoline, kerosene and other contaminants on solid surfaces. SpillAway+ is specially formulated to be SAFE, ENVIRONMENTALLY ENHANCING , FAST ACTING and both NON-CORROSIVE and NON-HAZARDOUS. |

| SpillAway+ Hydrocarbon Absorbent comes in: | |||

|

10 lb Plastic Jugs (4 per case) |

|||

| Satisfied users include | ||

|

US Air Force US Navy British Airways |

||

| FPT 600 - Food Grade Bio Cleaner & Degreaser |

|

FPT-600 food processing plant cleaner is an ideal general purpose cleaner-degreaser to be used in food processing plants and restaurants. It is has the unique ability to "digest" animal/vegetable greases, fats, oils, lipids & starches using a breakthrough microbial-enzymatic bioremediation process. |

Hotels/Motels/Inns/B&B's Dairy & Livestock General Home Kitchen Areas |

| FPT-600 is a breakthrough in the cleaning, maintenance and remediation of troublesome contaminant's in the food processing industry. This product utilizes BioRemediation technology to literally "EAT" animal and vegetable greases, oils, starches and lipids from all areas of a plant. FPT-600 at the same time remediates any hydrocarbons that may be present in production areas from leaking lubricant and hydraulic lines on your equipment (non-food contamination). FPT-600 is an excellent General Purpose cleaner. |

| FPT-600 General Purpose Cleaner comes in | ||

|

1 gal (4 per case) |

||

| Satisfied users include | ||

|

US Air Force US Navy British Airways |

||

Unasco Thread Seal Tape is a full density thread sealing tape mainly designed for lines carrying steam, water, and other liquids. Not only is this compatible with most liquids but also with a wide range of gases such as hydrogen, inert gases, kerosene, nitrogen, natural gas, etc. Being that this tape has not been stretched during the manufacturing process, it makes this a full density tape to to allow a very strong and effective seal. The tape is effective across a wide range of temperatures (-450°F to 500°F) and prevents galvanic corrosion of threads. Benefits of this tape are that it does not harden or crack on the joints, and acts as a thread lubricant and anti-seize. Other features include no curing time, non-toxic, non-flammable, and has an unlimited shelf life.

Unasco Thread Seal Tape is a full density thread sealing tape mainly designed for lines carrying steam, water, and other liquids. Not only is this compatible with most liquids but also with a wide range of gases such as hydrogen, inert gases, kerosene, nitrogen, natural gas, etc. Being that this tape has not been stretched during the manufacturing process, it makes this a full density tape to to allow a very strong and effective seal. The tape is effective across a wide range of temperatures (-450°F to 500°F) and prevents galvanic corrosion of threads. Benefits of this tape are that it does not harden or crack on the joints, and acts as a thread lubricant and anti-seize. Other features include no curing time, non-toxic, non-flammable, and has an unlimited shelf life.

| White Thread Seal Tape |

|

Medium Density Tape 0.7 g/cm3 | Chemically Resistant Operates from -450 F to +450 F | Available in 1/2" to 1" Sizes |

| Industrial Thread Seal Tape - The Pink Advantage |

|

Manufactured to a higher density 1.5 g/cm3 | Provides an impenetrable barrier to liquids & gases Suitable for a wide temperature range (-450 F to +500 F) | Suitable for Metal Pipes and Fittings Will not string or shred in use | Requires fewer wraps to seal |

| Yellow Gas Thread Seal Tape |

|

Specifically designed for petroleum, LPG & Natural Gases Manufactured to the highest density 1.5 g/cm3 | Provides an impenetrable barrier to gases Suitable for a wide temperature range (-450 F to +500 F) | Suitable for Metal Pipes and Fittings Certified by CSA (USA & Canada) & UL (Underwriters Laboratory) | Will not string or shred in use Requires fewer wraps to seal |

| Stainless Steel Thread Seal Tape |

|

Specifically designed for use in stainless steel pipe lines Impregnated with nickel powder to prevent galling or seizing | Manufactured to the highest density Provides an impenetrable barrier to gases | Suitable for metal pipes and fittings Will not string or shred in use | Requires fewer wraps to seal |

| Green Oxygen Thread Seal Tape |

|

Specifically designed for oxygen and other gases "Degreased " to enhance safety | Manufactured to the highest density Provides an impenetrable barrier to gases | Suitable for a wide temperature range (-450 F to +500 F) Suitable for degreased pipes and fittings | Will not string or shred in use Requires fewer wraps to seal |

| Gold High Density Tape |

|

Recommended for chemical application Manufactured to the highest density 1.5 g/cm3 | Provides an impenetrable barrier to gases Suitable for wide temperature range (-450 F to +500 F) | Will not string or shred in use Requires fewest wraps to seal |

| Copper Anti Seize Tape |

|

Designed to permit the easy assembly and disassembly of threaded components | Applied easily Instant release | Seals tightly Stops corrosion | Prevents rust No more seizures |