| Face Protection | Eye Protection | Head Protection | Hearing Protection | Respirators | Welding Helmets |

|

|||||

|

Superlok i-Fitting are the safest valve and fittings products in the instrumentation and control markets. We are so confident in the Superlok, Zero Leak Technology, that we back all i -Fittings products with a lifetime guarantee against leaks or failures! |

Superlok i-Fitting are the safest valve and fittings products in the instrumentation and control markets. We are so confident in the Superlok Zero Leak Technology, that we back all - fitting products with a lifetime guarantee against leaks or failures

Superlok i-Fitting are the safest valve and fittings products in the instrumentation and control markets. We are so confident in the Superlok Zero Leak Technology, that we back all - fitting products with a lifetime guarantee against leaks or failures

Superlok i-Fitting Tube fittings and valves | JIC Fittings | Ultra-High-Purity Fittings | DIN Fittings | Tubes | Coil | Flexible tube | Manifolds | High Pressure

Superlok i-Fitting - Built in Gap Gauge in Every Fitting Instrumntation Valves, Tube Fittings & Pipe Fittings.

![]()

![]()

![]()

![]()

![]()

![]()

Superlok i - fittings are the safest valve and fittings products in the instrumentation and control markets. We are so confident in the Superlok Zero Leak Technology, that we back all i - fitting products with a lifetime guarantee against leaks or failures.

Superlok i - fittings are the safest valve and fittings products in the instrumentation and control markets. We are so confident in the Superlok Zero Leak Technology, that we back all i - fitting products with a lifetime guarantee against leaks or failures.

Superlok i-Fitting - Built in Gap Gauge in Every Fitting Instrumntation Valves, Tube Fittings & Pipe Fittings. Superlok i-Fitting Tube fittings and valves | JIC Fittings | Ultra-High-Purity Fittings | DIN Fittings | Tubes | Coil | Flexible tube | Manifolds | High Pressure

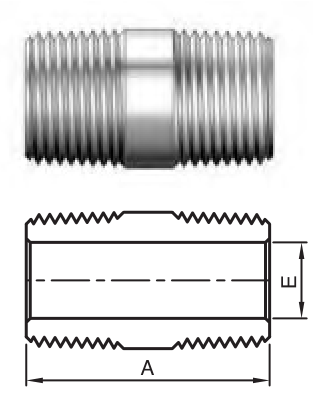

| Male NPT Threads | ||||||

| Male NPT Threads | ||||||

|

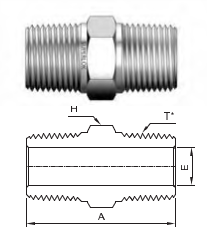

NOTE : In case of ISO/BSP(ISO 7/1) tapered pipe thread of T*, The part number should be “NR” instead of “N”

|

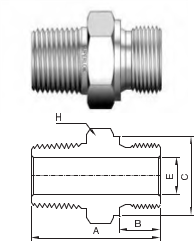

| Male NPT to Male ISO Parallel Pipe Threads | |||||||

|

|

| Male NPT Threads | ||||||

|

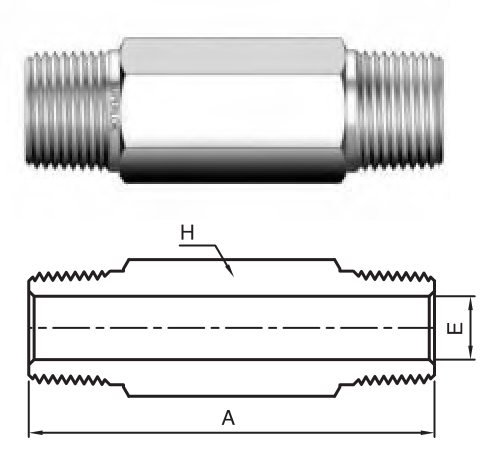

NOTE : The length of Nipple “A” is defined by user |

||||||

| Male NPT Threads | ||||||

|

NOTE : The length of Nipple “A” is defined by user

|

| Female to Male NPT Threads | ||||||

|

NOTE : In case of ISO/BSP(ISO 7/1) tapered pipe thread of T* The part number should be “NR” instead of “N”

|

| Female NPT to Male ISO Parallel Pipe Threads | |||||||

|

|

| Female to Male NPT Threads | |||||||

| Female to Male NPT Threads | |||||||

| Female NPT Threads | ||||||

| Female to Male NPT Threads | |||||||

| ISO Parallel Copper Gaskets | ||||||

| Female NPT Threads | ||||||

| Female NPT Threads | ||||||

| SBV120H Series | ||||

|

0.052˝ and 0.406˝ (1.3mm to 10.3mm) |

||||

| SBVI210 Series | ||||

|

5.0mm to 16.0mm |

||||

| SBVFI360 Series | ||||

|

1/16˝ to 3/4˝ and 4mm to 16mm Variety of end connection |

||||

| SBVHI360 Series | ||||

|

10.0mm to 19.0mm |

||||

| SWBI320 Series | ||||

|

-20 to 450°F (-28 to 232°C) with PVDF seat |

||||

| SGBV / SGBV2 Series | ||||

|

0.125” (3.2mm), 0.250” (6.4mm) |

||||

| Integral Bar Stock Bonnet Needle Valve SBNVI Series | ||||

|

0.17˝ and 0.25˝ (4.3mm and 6.4mm) |

||||

| SHCV SERIES | ||||

|

1/3, 1, 5, 10, 25 psig |

||||

| SOCV SERIES | ||||

|

VITON O-ring : -10°F to 375°F (-23°C to 190°C ) |

||||

| SRVL Series | ||||

|

4.8mm |

||||

| SRVH Series | ||||

|

4.8mm |

||||

| SPV130 Series | ||||

|

316 stainless steel |

||||

| STF Series | ||||

|

40°F to 250°F (- 40°C to 121°C) |

||||

| SIF Series | ||||

|

1/8 to 1/2 in. and 3 to 10mm |

||||